Joint Check

Joint Check

REVOLUTIONIZE YOUR WELDING INSPECTIONS WITH OUR SOFTWARE

Joint Check is designed specifically for managing welded and other connections between pipes and fittings. It enables users to track heat numbers, production status, fit-up, welding, fit-up inspections, welding inspections, and generate all kinds of reports about daily progress, repair jobs, welder performance, welder qualifications, and more.

With Joint Check, users can easily track the status of production processes, from initial fit-up to final welding and inspection. The software provides real-time updates on production progress, allowing users to identify potential issues and take corrective action before they become major problems. Additionally, Joint Check provides comprehensive reporting capabilities, enabling users to generate detailed reports on a wide range of metrics, including daily progress, repair jobs, welder performance, and more.

Features

- QA/QC Documentation from Fit-Up to Installation

- Live Backlog for Weld Inspections

- Tracking of Joint Status in the Shop and in the Field

- Tracking of Fitter/Welder Qualifications & Performance

- Tracking of Materials

- Tracking of WPS/WPQR for each Joint

- Full Traceability of all Materials and Activities for each Joint

- Runs on PCs, Tablets & Smartphones

- Data is saved in your own Cloud Environment

Features

- QA/QC Documentation from Fit-Up to Installation

- Live Backlog for Weld Inspections

- Tracking of Joint Status in the Shop and in the Field

- Tracking of Fitter/Welder Qualifications & Performance

- Tracking of Materials

- Tracking of WPS/WPQR for each Joint

- Full Traceability of all Materials and Activities for each Joint

- Runs on PCs, Tablets & Smartphones

- Data is saved in your own Cloud Environment

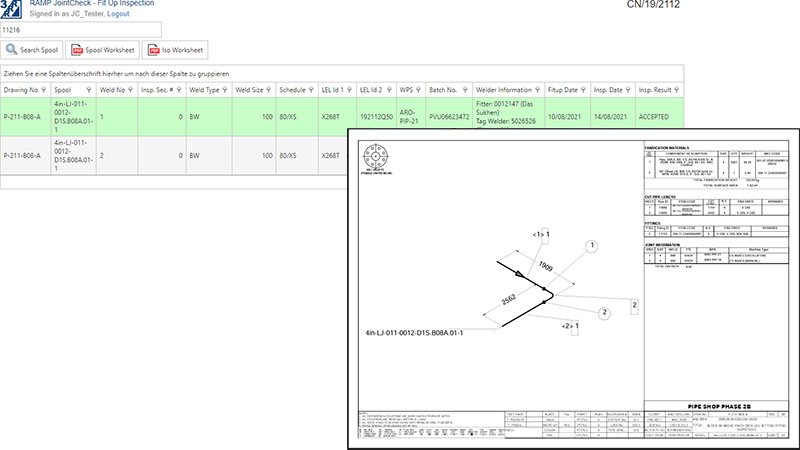

YOUR QA/QC INSPECTION ASSISTENT

The inspectors can completely focus on the tracking of inspection details, there is no need to enter design information about all of the project’s joints like sizes, materials, joint numbers, etc. These are already prefilled as Joint Check has already processed the spool drawings with the help of IsoBuilder.

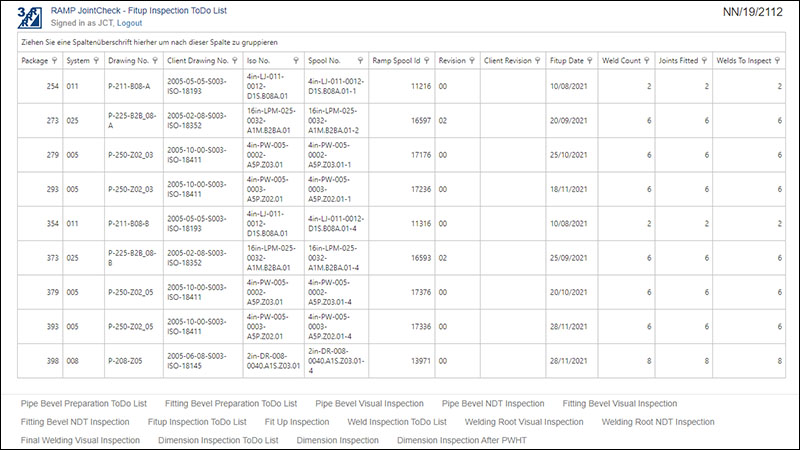

Joint Check provides a live backlog of all welds to be inspected and their current location in the shop. It also informs about live NDT coverage information to assist the inspector as much as possible selecting welds to be tested. It is the perfect tool to assure that your documentation of joints is complete and of the highest quality.

Joint Check provides a live backlog of all welds to be inspected and their current location in the shop. It also informs about live NDT coverage information to assist the inspector as much as possible selecting welds to be tested. It is the perfect tool to assure that your documentation of joints is complete and of the highest quality.

QA/QC REPORTING

Joint Check automatically generates QA/QC reports based on your individual needs. It covers QA/QC mandatory reports, such as:

- (Daily) Fit-Up Inspection Report

- (Daily) Welding Report

- Pressure Test Report

- Spool Control Sheet

- Weld Inspection Summary Report

- Various NDT Reports

- Fitter Performance Report

- Welder Performance Report

- List of Approved Fitter and Welders

- Welding History Report

- And Others

Use on mobile devices

Joint Check is optimized for mobile operations on tablet devices for inspectors. This provides you with the flexibility to obtain information from anywhere in the pipe-shop or at the installation site.

If your spools are labeled with barcodes or QR-codes you can easily let Joint Check identify the list of corresponding joints using the device’s camera. After the scanning you can directly start the tracking and input of results.