RAMP

RAMP

Automate and control your pipe spool fabrication

Features

- Pipe-Shop Control

- Material Planning & Remnant Management

- Workload Balancing for all Machines

- Monitoring of Progress and Dates

- Calculation of Work Time

- Material Nesting / Cutting Optimization

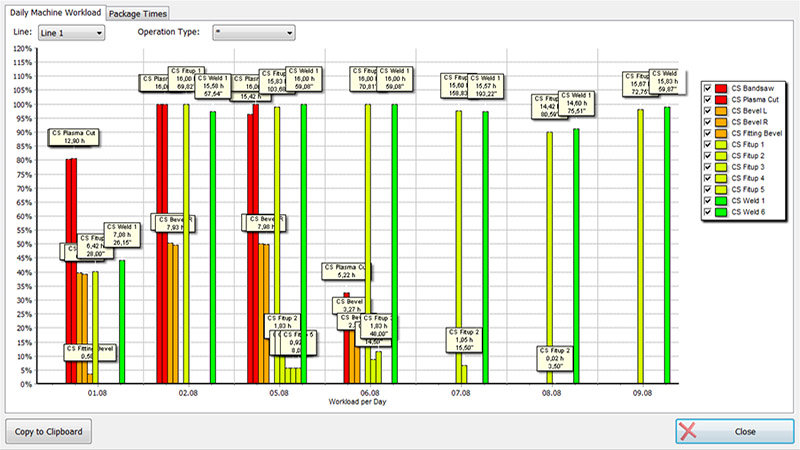

- Calculation of Capacities

- Paperless Pipe Processing

Features

- Pipe-Shop Control

- Material Planning & Remnant Management

- Workload Balancing for all Machines

- Monitoring of Progress and Dates

- Calculation of Work Time

- Material Nesting / Cutting Optimization

- Calculation of Capacities

- Paperless Pipe Processing

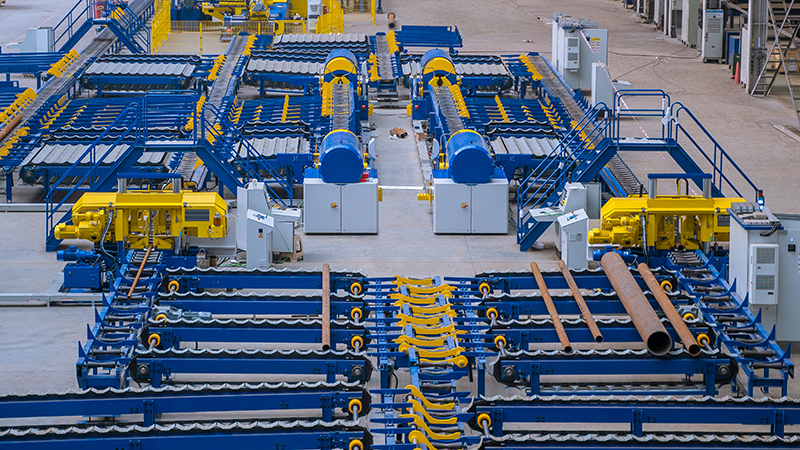

Pipe-Shop Control

Each installation of RAMP is customized to cater for our customers‘ individual requirements, as every workshop holds different storage options, machines and transport systems. Furthermore every fabrication process needs to address different key aspects.

The fabrication status assigned to a component by the RAMP-system can be checked retroactively in IsoBuilder. This way the up-to-date progress in the pipe-shop for finished isometries can be determined at any time.

Material Planning & Management

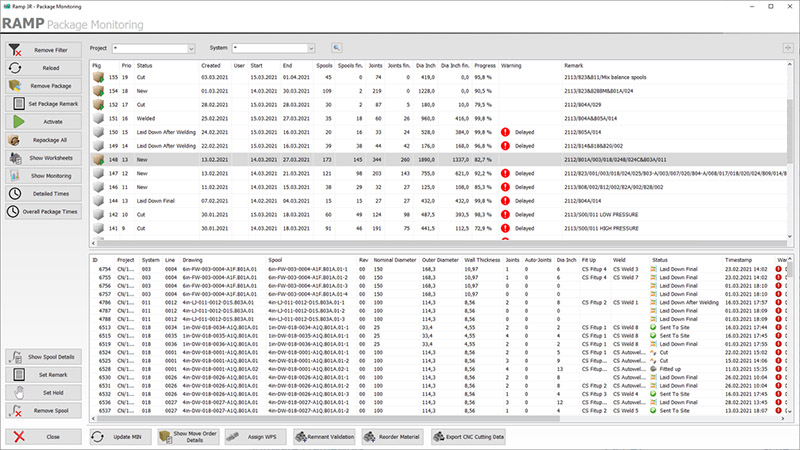

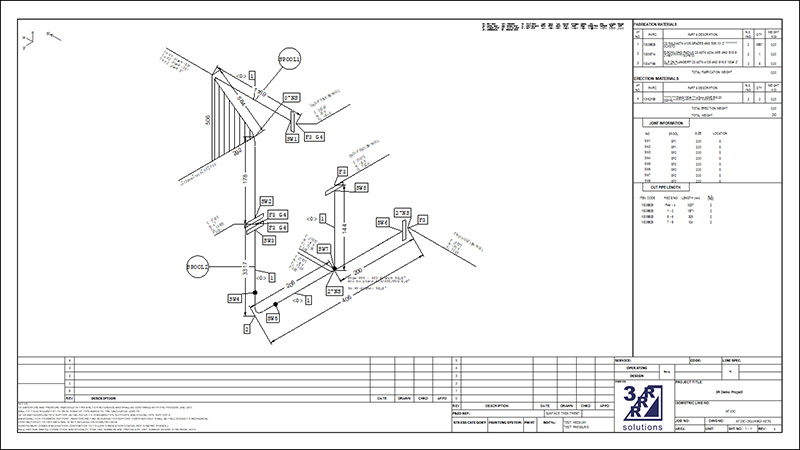

For RAMP each drawing (e.g. from IsoBuilder) contains not only the displayed drawing, but all fabrication relevant contents, such as welding points, bending values, pipe lengths, spool weight, as well as all installed materials. The entire order process, allocation of material, the welding documentation, as well as following material statistics can be realized by RAMP.

Monitoring of Progress and Dates

Calculation of Work Time

Work Preparation

Modification Management

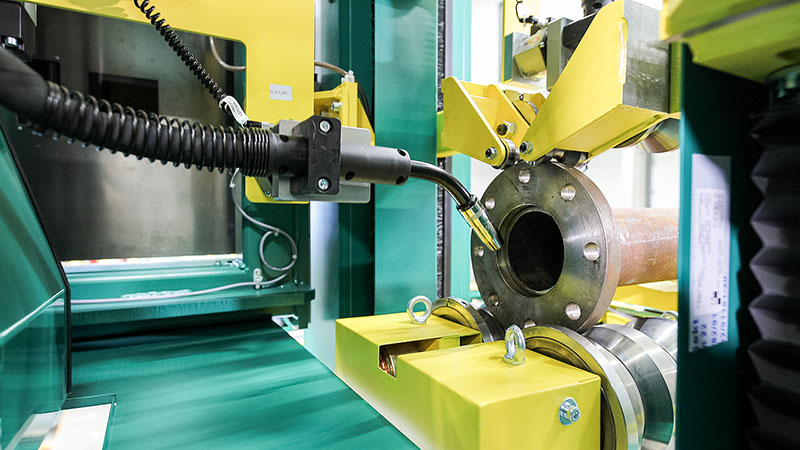

Machine Control

Every CNC machine can be equipped with a RAMP-Client. This way CNC data can be transferred directly to the machine, and after the relevant fabrication step is executed, the status of the component can be updated. Afterwards the software specifies the next operation, and the pipe spool is transported to the next station if required. Fabrication at each workstation can thus be reduced to a simple push of a button.