Kolli

Kolli

All you need for tube bending in a single application

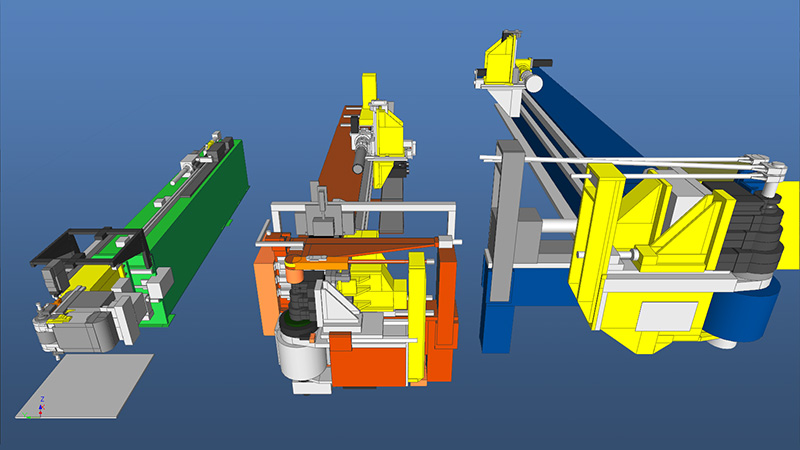

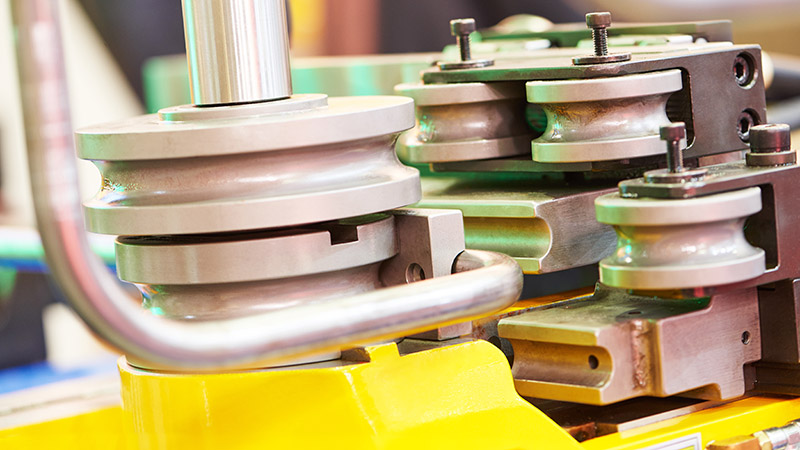

Kolli supports both simple mandrel bending machines as well as modern right- and left-bending machines with multiple bending heads and levels. In addition to standard mandrel bending with bending die Kolli also simulates roller and induction bending.

Key Numbers

- More than 200 Customers worldwide use Kolli for their Bending Jobs

- Support for 30 Machine Types from various Manufacturers

Key Numbers

- More than 200 Customers worldwide use Kolli for their Bending Jobs

- Support for 30 Machine Types from various Manufacturers

Features

- Tube Bending Simulation and Feasibilty Analysis

- Independent from Machine Manufacturers

- Quick Customization of new Machine Types

- Collision Detection and Collision Avoidance Strategies

- Support for multiple Bending Heads and Levels

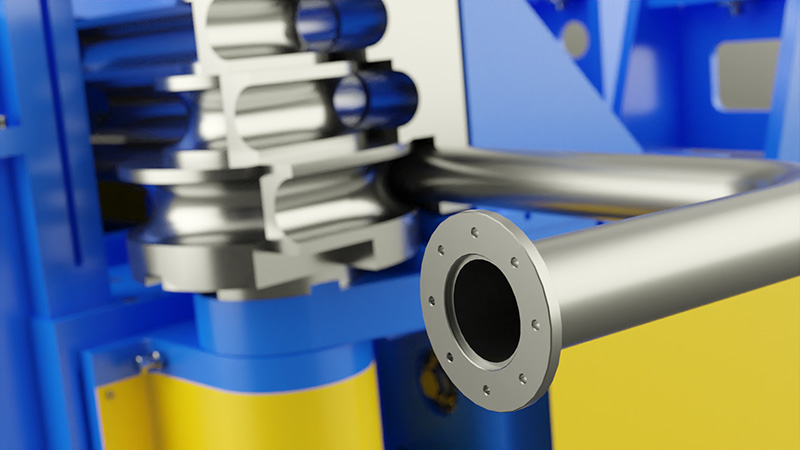

- Support for Mandrel and Roller Bending Machines

- Generation of customizable Bending Reports

- Generation of CNC Data and Transfer to the Machines

- Manual Creation of Tube Geometries in Isometric View

- Import of Tube Geometries from CAD Files (STEP, IGES and more)

- Automatic Correction with Data from Measuring Systems

- Support for Bending with End Preparations or Flanges

- Support for Printing and Marking

Features

- Tube Bending Simulation and Feasibilty Analysis

- Independent from Machine Manufacturers

- Quick Customization of new Machine Types

- Collision Detection and Collision Avoidance Strategies

- Support for multiple Bending Heads and Levels

- Support for Mandrel and Roller Bending Machines

- Generation of customizable Bending Reports

- Generation of CNC Data and Transfer to the Machines

- Manual Creation of Tube Geometries in Isometric View

- Import of Tube Geometries from CAD Files (STEP, IGES and more)

- Automatic Correction with Data from Measuring Systems

- Support for Bending with End Preparations or Flanges

- Support for Printing and Marking

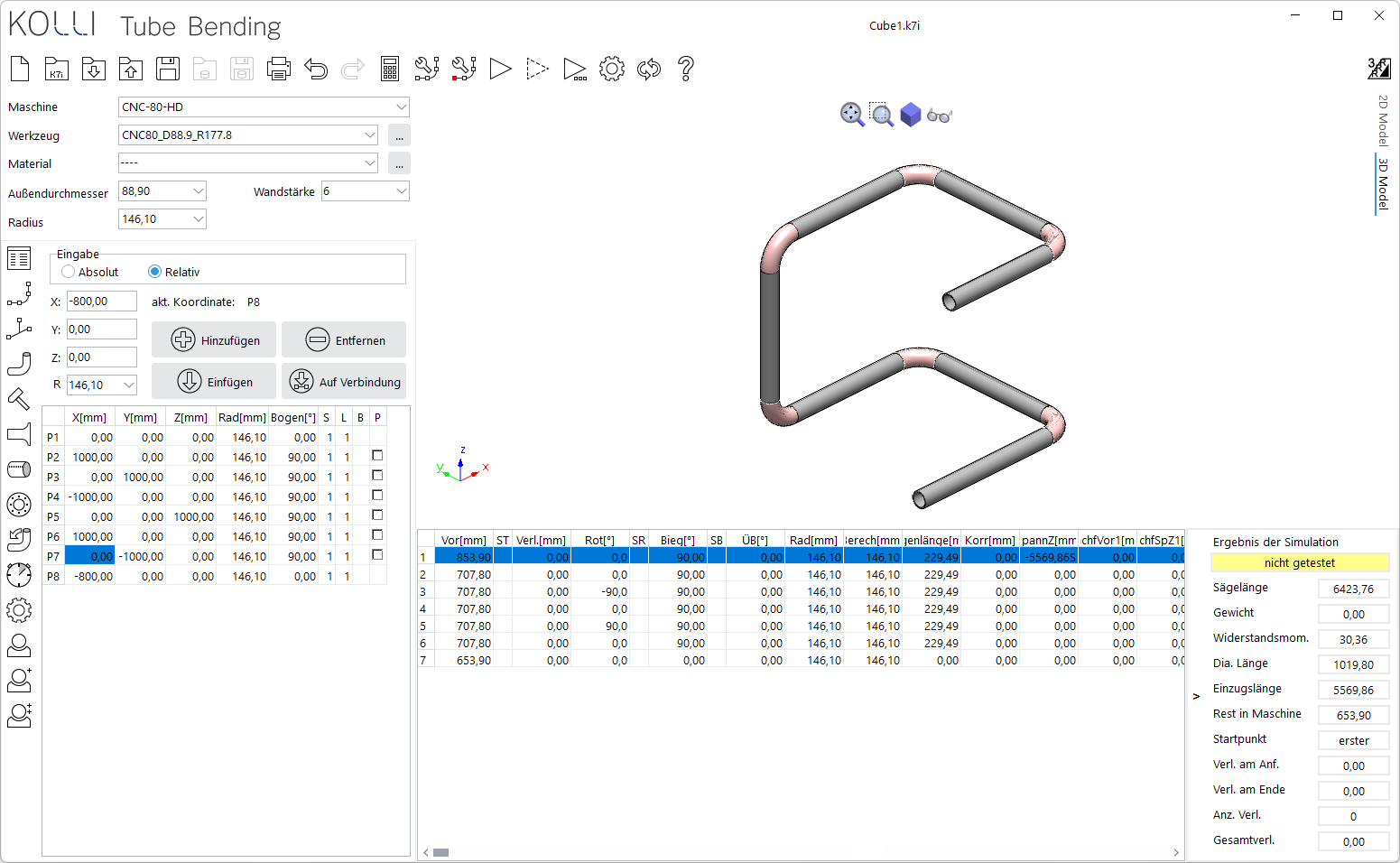

Bending Simulation

- Change of rotation direction

- Addition of correction feed

- Change of bending direction

- Change of bending head

- Change of bending level

- Change of bending sequence at tool change or retraction of bending arm (depending on machine type)

- Leg elongations

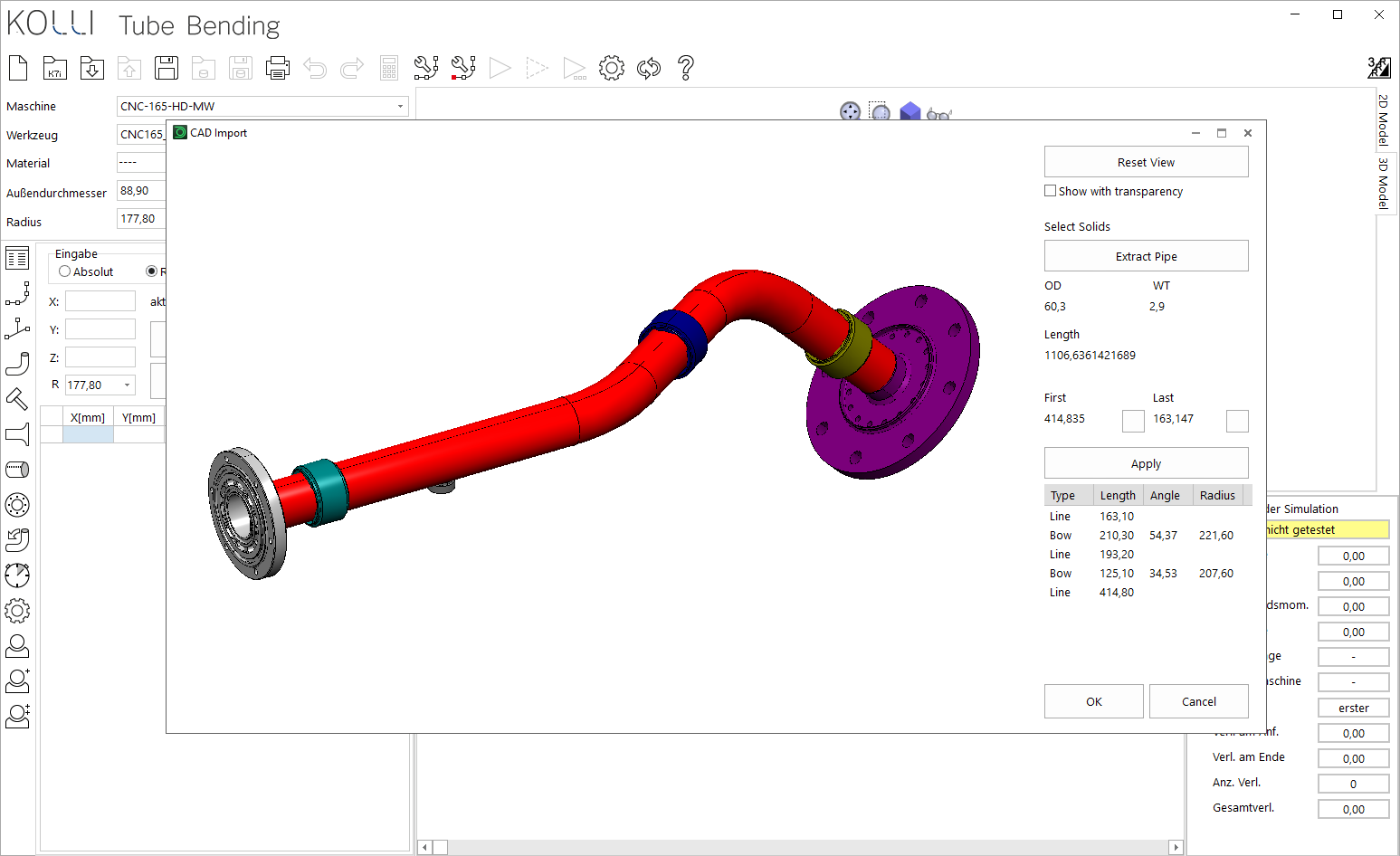

Import & Export Interfaces

A continuously growing number of interfaces enables the import and export of data. These interfaces allow the control of CNC bending machines as well as the import of tube geometries from third-party systems, like measuring systems or CAD platforms.

Important and common import formats are:

- STEP

- IGES

- Text (XYZ, customizable CSV format)

- Excel

- PCF (for bends in pipeline systems)

The import supports reading the full 3D CAD models through STEP and IGES files containing end preps, supports, etc. The user can select the entities of interest and Kolli automatically scans these for tubes to import.

Additional import and export formats can be added on request.

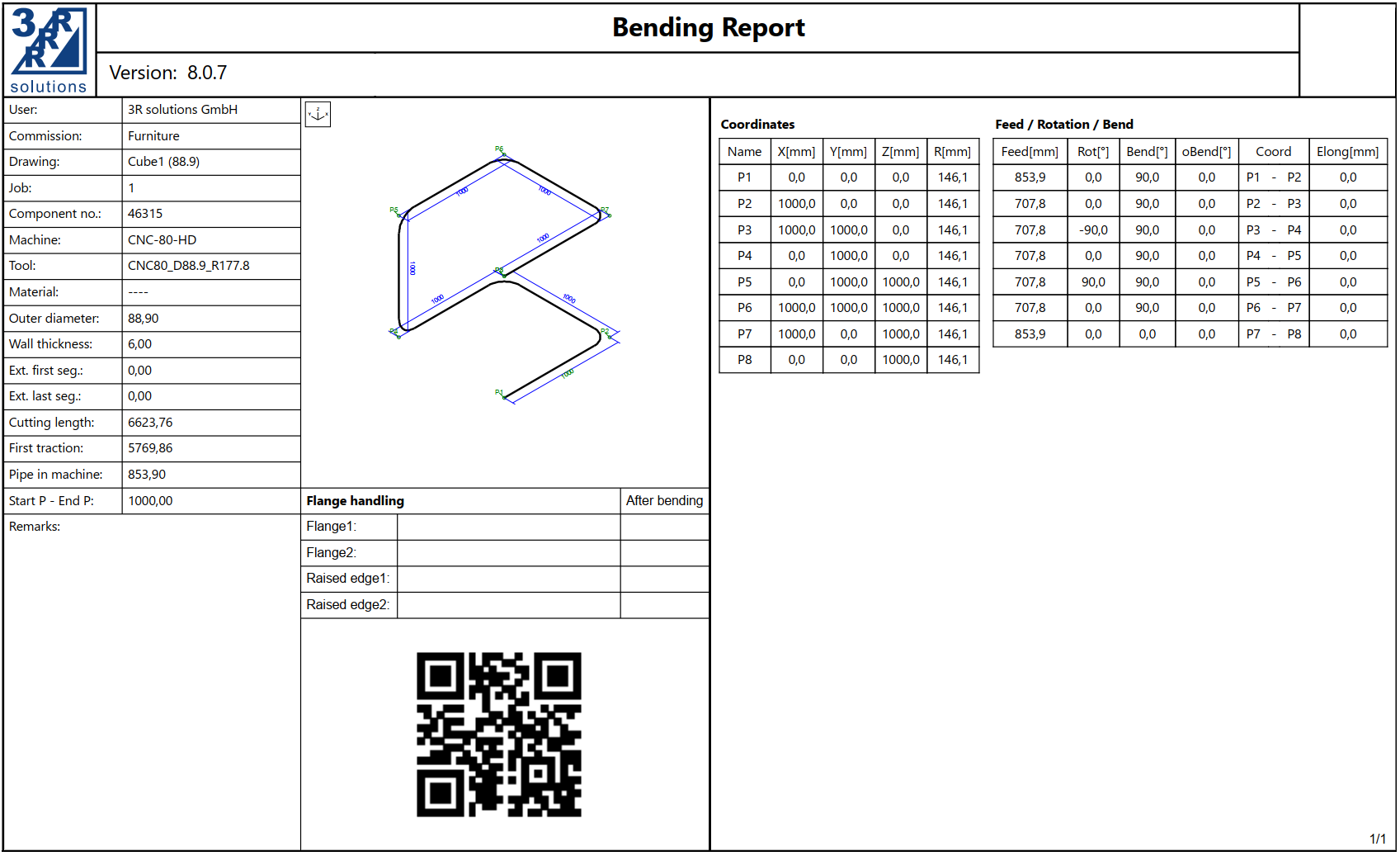

Generating CNC Data & Reporting

Apart from machine data Kolli generates according bending reports containing the material and bending parameters. The appearance of the reports is highly customizable.

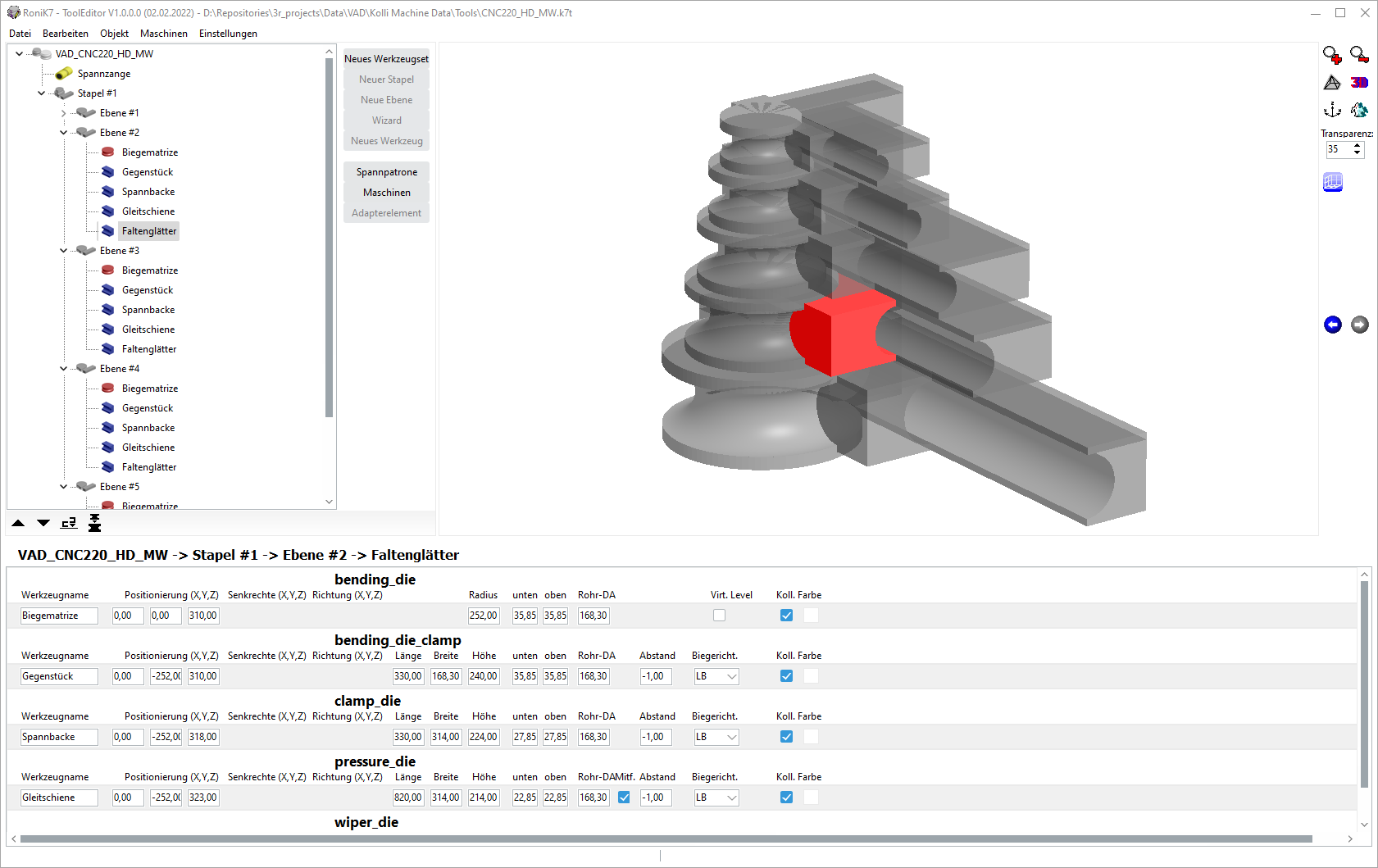

Machine and Tool Management

Material Management

The Material Manager administers the material-specific properties of the tubes, bars and profiles. Especially in unit production of tubes it is essential to achieve a precise bending result on first try. Using the Material Manager empirically derived material properties can be collected and recorded easily. The information serves the fitting accuracy of the pipelines to be bent and the generation of CNC data. It is used to calculate precise cutting lengths, considering the material’s springback, the reduction in traction lengths caused by overbending and the bend’s radius increase, as well as the material stretching inside the bend.

BATCH Testing of Multiple Products on multiple Machines

Bending with End Preparations or Flanges

Cycle Times

For each tube geometry Kolli determines a machine-dependent theoretical cycle time. This way the speed and efficiency of axis movement sequences or several machines and can be compared directly for optimizations in mass production.