Integrated Piping

Integrated Piping

Bridging the Gap between Engineering and Fabrication

Connectivity

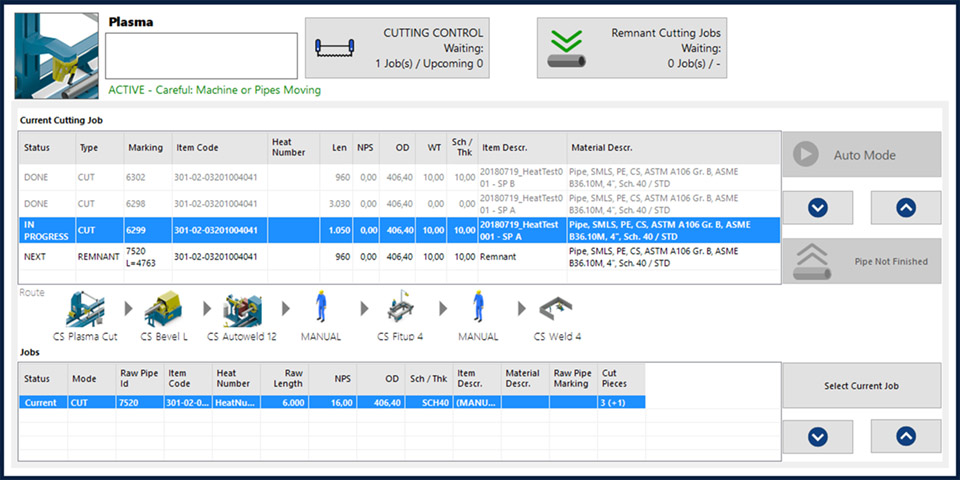

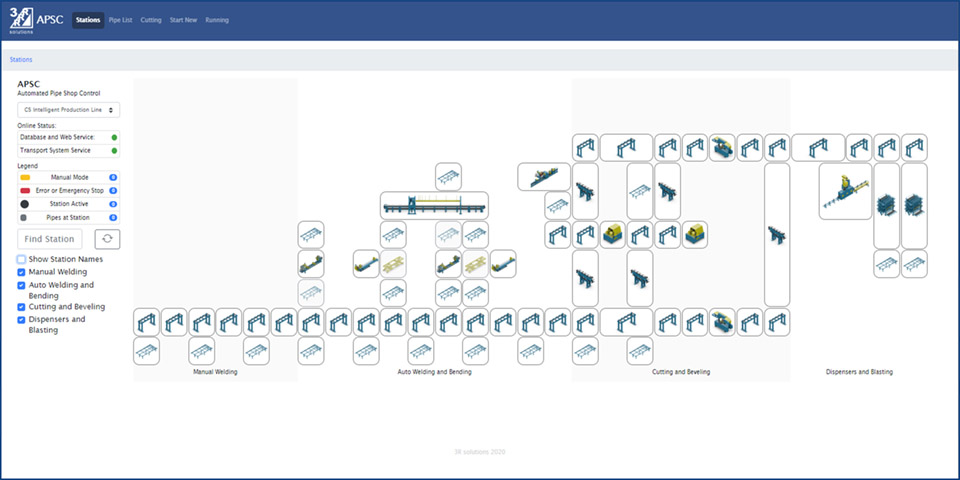

In our automated pipe-shops every machine and workstation is connected to a central database that stores all fabrication data. This database makes it possible to transmit data from engineering to the shop floor.

Furthermore the various stations and machines are able to communicate with each other, so for instance the band saw can request a new pipe from the dispenser after completing a cutting job.

Real-Time Data

All stations and the automated transport system inside the pipe-shop are equipped with sensors, providing real-time monitoring capabilities.

General feedback from the machines includes processing start and finish times, or machine utilization, while advanced sensor data lets you record auto-welding metrics. Data is also collected for important KPIs, e.g. DIA inch per station, and transmitted to the central database.

Production Control

Using sensor data and other data gathered at each station, the entire fabrication process can be monitored and controlled using a model of the actual pipe-shop.

The software determines the ideal route for each pipe, and the ideal fabrication order of all pipes. Each pipe’s location inside the shop can be tracked in real-time, as each pipe is marked with a unique ID that makes it identifiable at every station.

Smart Pipe Spool Fabrication

Software integration is a key factor in our pipe-shops, as it facilitates a high degree of automation and control of the entire fabrication process, from managing the warehouse inventory to keeping track of the installation status.

The central database, where all fabrication data is stored, is accessible from inside the pipe-shop, as well as the engineering and management offices. It is used to transmit CNC data to the machines and to receive status updates from them concerning their current processing jobs.

Pipes and fittings are marked with ID numbers, barcodes or QR codes, so they can be identified at every position inside the shop. Not only does this enable machines to retrieve CNC parameters from the database and workers at fit-up and welding stations to quickly access spool details, it also allows the transport system to automatically move pipes to the next processing station, saving valuable time.

As a high and consistent quality is essential, our software collects all relevant data such as time and duration of processing, welding metrics, fitter and welder IDs, and more. In addition to being able to monitor the fabrication process as it is happening, you can also trace back each part and welding seam of every spool that is fabricated in your pipe-shop.

Smart Pipe Spool Fabrication

Software integration is a key factor in our pipe-shops, as it facilitates a high degree of automation and control of the entire fabrication process, from managing the warehouse inventory to keeping track of the installation status.

The central database, where all fabrication data is stored, is accessible from inside the pipe-shop, as well as the engineering and management offices. It is used to transmit CNC data to the machines and to receive status updates from them concerning their current processing jobs.

Pipes and fittings are marked with ID numbers, barcodes or QR codes, so they can be identified at every position inside the shop. Not only does this enable machines to retrieve CNC parameters from the database and workers at fit-up and welding stations to quickly access spool details, it also allows the transport system to automatically move pipes to the next processing station, saving valuable time.

As a high and consistent quality is essential, our software collects all relevant data such as time and duration of processing, welding metrics, fitter and welder IDs, and more. In addition to being able to monitor the fabrication process as it is happening, you can also trace back each part and welding seam of every spool that is fabricated in your pipe-shop.